⚡ Energy Management System

PKT continuously performs continual improvement on energy performance and energy management system performance while considering environmental sustainability in accordance with PKT's energy conservation policy.

PT Pupuk Kalimantan Timur has been certified with the Energy Management System ISO 50001:2018 with the scope of Ammonia and Urea Production PKT-1A, PKT-2, PKT-3, PKT-4, and PKT-5. In fulfilling compliance with Government Regulations on Energy Conservation, Pupuk Kaltim has appointed certified energy managers, developed energy conservation programs, conducted regular energy audits by certified auditors, implemented energy audit results, and reported energy conservation implementation to the government annually.

📊 Online Energy Management Reporting (POME) Pupuk Kaltim

PT Pupuk Kalimantan Timur has been certified with the Energy Management System ISO 50001:2018 with the scope of Ammonia and Urea Production PKT 1A, PKT 2, PKT 3, PKT 4, and PKT 5. In fulfilling the requirements of Government Regulations on Energy Conservation, Pupuk Kaltim has appointed certified energy managers, developed energy conservation programs, conducted regular energy audits by certified auditors, implemented energy audit results, and reported energy conservation implementation to the government annually.

Annual POME Reports

💧 Water Efficiency Policy and Wastewater Pollution Load Reduction

As a company operating in the fertilizer industry sector, Pupuk Kaltim positions water management as one of the main priorities in efforts to maintain environmental sustainability. The company is committed to implementing water use efficiency and reducing wastewater pollution load sustainably through the implementation of the Water Efficiency Policy and Wastewater Pollution Load Reduction. This policy serves as the foundation for strategic planning, goal setting, and implementation of various water management programs that are aligned with the company's environmental policies.

In its implementation, Pupuk Kaltim targets a 1% reduction in water use and a 0.5% reduction in wastewater pollution load within a five-year timeframe. These targets serve as benchmarks for the company's success in improving water resource efficiency while maintaining the quality of wastewater generated from operational activities.

📊 Water Audit

As part of its commitment to improving environmental performance, Pupuk Kaltim regularly conducts Water Audits. As a chemical process-based industrial company, PT Pupuk Kalimantan Timur (PKT) has a high commitment to sustainable water resource management. The water management audit results show that PKT fully utilizes seawater as the main source for its production processes, thus not depending on limited freshwater sources that have high ecological value.

Seawater Utilization

Primary water source for production processes

Freshwater Conservation

Independent from limited freshwater resources

High Ecological Value

Protecting water resources with ecological value

Effectiveness Assessment

Evaluation of operational water management

Regulatory Compliance

Meeting environmental regulations and standards

Continuous Improvement

Sustainable water management innovation

This activity is conducted to assess the effectiveness of water management across all operational lines, identify efficiency potential, and ensure compliance with applicable environmental regulations and standards. Audit results are used as the foundation for developing improvement measures and more sustainable water management innovations.

🎯 Five-Year Water Efficiency Targets

Pupuk Kaltim sets ambitious water efficiency targets for the next five years. These targets are designed based on in-depth analysis of water consumption patterns, latest water management technologies, and the company's commitment to sustainable water resource management in accordance with the Sustainable Development Goals (SDGs).

Water Usage Reduction Target

Efficiency in water resource utilization

Wastewater Pollution Load Reduction Target

Wastewater quality from operational activities

These targets serve as benchmarks for the company's success in improving water resource efficiency while maintaining the quality of wastewater generated from operational activities. Achieving these targets demonstrates PKT's commitment to responsible and sustainable water management.

💡 Water Treatment Innovation and Technology

Furthermore, Pupuk Kaltim continues to promote innovation and implementation of efficient and environmentally friendly water treatment technologies, both through production process optimization and water recycling system development. This step is a concrete manifestation of the company's commitment to creating responsible industrial operations, efficient in resource utilization, and supporting the achievement of Sustainable Development Goals (SDGs).

Production Process Optimization

Water Recycling System

Responsible Operations

Environmentally responsible industry

Resource Efficiency

Efficient resource utilization

SDGs Support

Achieving Sustainable Development Goals

Through the implementation of innovative and sustainable water treatment technologies, PKT not only meets the established efficiency targets but also actively contributes to maintaining water resource sustainability for future generations, aligned with global commitment to responsible water management.

⚠️ Water Risk Management

In addition to climate change risks, Pupuk Kaltim also recognizes that this causes unpredictable weather and seasonal patterns. Although Pupuk Kaltim is not located in an area vulnerable to water scarcity, Pupuk Kaltim also strives to manage water wisely as a form of contribution to reducing the impact of climate change. As a further effort in water management, Pupuk Kaltim has conducted desalination to convert seawater into freshwater that can be utilized for production needs. Furthermore, Pupuk Kaltim has also conducted risk analysis regarding groundwater utilization.

Water-related risks identified by Pupuk Kaltim are as follows:

🏭 Groundwater Dependency

Dependency on deep groundwater needs for supporting facilities, while deep groundwater is limited in quantity and its extraction is restricted by the government.

💡 Mitigation:

Utilization of rainwater for toilet flushing in offices and utilization of AC condensation water as a source of clean water in offices.

💧 Decrease in Water Quantity and Quality

The impact of increased water usage causes risks of decreased freshwater quantity and quality, which can indirectly reduce the availability of clean water from nature.

💡 Mitigation:

Tree planting programs and forest preservation in company areas to increase rainwater and surface water absorption into the ground. Forests with good ecosystems will naturally purify surface water.

🌊 Limited Freshwater Supply

There is a risk of limited freshwater supply, while water demand is predicted to increase in the future.

💡 Mitigation:

Construction of water collection ponds to store surface water for use as freshwater in Industrial Support areas.

🔬 Impact of Product Use on Water Quality

There is a risk of declining water quality in the future that could affect operations and the environment.

💡 Mitigation:

Ensuring that wastewater pollutant levels discharged to the environment do not exceed the thresholds set by the government.

👥 Community Water Needs

Risk of increased groundwater demand for domestic purposes in buffer zone communities due to population growth around industrial areas.

💡 Mitigation:

Providing Corporate Social Responsibility (CSR) assistance in the form of raw water to surrounding communities.

📋 SIPA Permit Restrictions

Government restrictions on issuing Groundwater Business Permits (SIPA) while the company's freshwater needs are increasing, and producing water from seawater requires considerable cost and energy per m³ of freshwater product.

💡 Mitigation:

Creating water use efficiency programs and building rainwater collection ponds for use as industrial water.

🌾 Environmental Impact of Over-fertilization

Risk:

Over-fertilization can potentially cause environmental impacts. Excessive phosphorus nutrients can potentially be carried in groundwater movement. Under certain conditions, this can cause eutrophication phenomena from excessive phosphorus nutrients in water bodies.

💡 Mitigation:

Pupuk Kaltim has developed and implemented PreciPalm in oil palm plantations across various regions in Indonesia. Through fertilization dose recommendations based on actual and precise satellite imagery, PreciPalm ensures targeted and efficient fertilizer dose recommendations, while preventing over-fertilization and mitigating environmental impacts.

🌱 Climate Strategy & Risk Management

Pupuk Kaltim is committed to addressing climate change through focused and sustainable decarbonization strategies towards Net Zero Emission 2060.

🌱 Climate Strategy

Pupuk Kaltim is committed to addressing climate change through focused and sustainable decarbonization strategies. As part of our efforts towards Net Zero Emission 2060, the company implements various mitigation and adaptation initiatives to reduce emissions, improve energy efficiency, and strengthen operational resilience against extreme climate risks.

In the short term, Pupuk Kaltim focuses on energy efficiency and emission control in production processes. In the medium term, the company expands the implementation of low-carbon technologies and develops green products such as green ammonia. Meanwhile, in the long term, Pupuk Kaltim targets transformation towards a sustainable chemical company based on circular economy through green product innovation and the implementation of carbon capture and utilization (CCU) technology.

This strategy is implemented with strong sustainability governance under the supervision of the Board of Commissioners Committee and cross-functional ESG Team, ensuring every step towards green energy transition is measured and impactful.

⚡ Climate Change Risks and Opportunities

As part of our commitment to supporting the transition to a green economy and Indonesia's Net Zero Emission 2060 target, Pupuk Kaltim actively identifies, manages, and integrates climate-related risks and opportunities into the Company's strategic and operational planning. Climate risk management is carried out through identification and mitigation of physical and transition risks in the upstream to downstream sectors, to identify potential impacts and develop mitigation and adaptation plans.

This approach is integrated into the Enterprise Risk Management (ERM) system and implemented through energy efficiency, utilization of low-carbon technology, implementation of circular economy, adaptation of business processes to short-term to long-term climate change, and sustainability reporting based on ESG and TCFD. With these steps, Pupuk Kaltim ensures operational sustainability and makes real contributions to national energy transition.

To strengthen oversight, Pupuk Kaltim adopts ISO 31000:2018, by integrating climate-related risks and opportunities into the ERM process. These risks and opportunities are reported monthly to the Risk Management Director and quarterly to the Risk Monitoring Committee, to ensure continuous monitoring and alignment with Net Zero targets.

Pupuk Kaltim has summarized the main climate-related risks and opportunities for 2024, along with the mitigation measures that have been implemented in response to these issues, as follows:

Physical Risk

Transition Risk

Opportunities / Upside Risk

🎯 Net Zero Emission 2060 Commitment

Through comprehensive climate strategy and integrated risk management, Pupuk Kaltim is committed to achieving the Net Zero Emission 2060 target while maintaining sustainable operations and contributing positively to the national energy transition.

🌱 Environmental Sustainability

PT Pupuk Kalimantan Timur is committed to becoming an environmentally responsible company through the implementation of a comprehensive and sustainable environmental management system. As a fertilizer and chemical company, we understand the importance of maintaining the balance between business productivity and environmental conservation for future generations.

Our environmental commitment is realized through the implementation of international standards, green technology innovation, environmental impact reduction, and development of competent human resources in the environmental field. Through this holistic approach, PKT strives to create sustainable value for all stakeholders.

Every operational step of the company is designed by considering environmental aspects, ranging from energy efficiency, emission management, water conservation, to responsible waste management in accordance with circular economy principles.

📋 Implementation of ISO 14001:2015 Environmental Management System

PT Pupuk Kalimantan Timur (PKT) is strongly committed to maintaining environmental sustainability through the implementation of an Environmental Management System (EMS) that refers to the SNI ISO 14001:2015 standard. This certification is provided by Sucofindo International Certification Service (SICS) with the scope of Manufacturing of Ammonia, Urea, and NPK. Through the implementation of this international standard, PKT ensures that all company operational activities are carried out systematically, measurably, and in accordance with environmental sustainability principles.

As part of EMS implementation, PKT routinely conducts internal and external audits to assess system effectiveness, regulatory compliance, and opportunities for continuous improvement. The audit scope covers important aspects such as energy efficiency, emission management, water usage, wastewater treatment, hazardous (B3) and non-hazardous waste management, as well as biodiversity protection. In addition to EMS, PKT has also implemented the ISO 50001 Energy Management System and ISO 45005:2020 Occupational Health and Safety Management System, to ensure synergy between productivity, energy efficiency, and environmental responsibility.

As a follow-up to audit results, PKT continues to develop various environmentally friendly programs such as waste management optimization, emission reduction, energy and water conservation, and increasing employee environmental awareness through education and training. PKT is also actively conducting socialization to the community and employees regarding the importance of environmental conservation and good waste management practices, to foster an environmental care culture throughout the company ecosystem.

🏭 Green Industry Implementation

In an effort to run a sustainable business, PKT is committed to implementing Green Industry Policy as an integral part of the Company's Integrated Management System. This approach is guided by the principle of Risk Based Thinking, which ensures that every operational activity, from planning to evaluation, comprehensively considers potential risks and environmental impacts.

PKT's Green Industry Policy includes efforts to improve resource efficiency, reduce carbon emissions, and implement circular economy principles through the reuse of materials and energy from production processes. Through this strategy, PKT not only ensures operational sustainability, but also contributes to national targets for greenhouse gas emission reduction and low-carbon economic development. The implementation of this policy demonstrates PKT's commitment to becoming a pioneer in implementing green industry in the national fertilizer sector.

👨🎓 Environmental Human Resources Competency Development

PKT believes that successful environmental management is not only determined by systems and technology, but also by the competency of human resources (HR) who implement them. Therefore, the company ensures that all personnel with environmental responsibilities have competency certificates from the National Professional Certification Agency (BNSP).

In addition, PKT has also formed an Environmental Management System Team consisting of certified professionals experienced in implementing ISO standards. Through training, socialization, and other internal activities, the company continues to improve awareness and HR capacity to be able to identify, manage, and minimize environmental risks in their respective work areas.

This step is in line with PKT's vision to become a globally competitive fertilizer and chemical company, operating responsibly, and providing sustainable added value for the environment and society.

💰 Environmental Investment Costs

The company is committed to continuously improving its environmental performance through various innovation efforts and business development oriented towards sustainability principles. This commitment is realized through investment in a number of strategic initiatives to improve environmental performance and reduce carbon emissions, including through the construction of the Soda Ash Project, Revamping Ammonia Plant 2, waste management, and various other initiatives. All of these efforts not only strengthen environmental performance and support sustainability goals, but also provide added value for the company's financial and operational performance.

Investment Programs to Support Environmental Sustainability Commitment

♻️ Waste Management System

As part of our commitment to responsible and sustainable environmental management, Pupuk Kaltim implements a comprehensive Waste Management System that covers the management of Hazardous and Toxic Waste (B3), Non-B3 Waste, and General Waste.

All management activities are carried out in an integrated manner with the principles of reduce, reuse, recycle (3R), implementation of circular economy, and compliance with applicable regulations, in order to minimize environmental impact and support the achievement of Sustainable Development Goals (SDGs).

⚠️ Hazardous and Toxic Waste (B3)

Pupuk Kaltim recognizes that industrial activities have the potential to generate hazardous and toxic waste (B3) that requires special handling to prevent risks to the environment and occupational health.

As a form of environmental responsibility, the company implements the B3 Waste Reduction and Utilization Policy to ensure that all management processes are carried out safely, responsibly, and in accordance with applicable legal provisions.

Target for B3 Waste Reduction

B3 Waste Generation Target 2024

Through this policy, Pupuk Kaltim targets a 7% reduction and utilization of B3 waste over a five-year period. In 2024, the target for B3 waste generation is no more than 33,319.96 metric tons. This target serves as the foundation for the company's commitment to continuously minimize waste generation and expand B3 waste utilization through the consistent implementation of 3R principles (reduce, reuse, recycle) across all operational lines.

🔄 Non-B3 Waste

As part of our sustainable environmental management strategy, Pupuk Kaltim has also established a Reduce, Reuse, Recycle (3R) Policy for Non-B3 Waste.

The company focuses on reducing the generation of non-B3 solid waste, including registered waste such as fly ash and bottom ash (FABA), by prioritizing a Life Cycle Assessment (LCA) approach and supporting the achievement of SDGs.

Non-B3 Registered Waste Utilization Target

Optimization of FABA utilization as substitute materials or valuable construction materials

Through this policy, the company targets 50% utilization of registered Non-B3 waste over a five-year period. These efforts are carried out through the optimization of FABA utilization as substitute materials or valuable construction materials. The utilization percentage compared to total generation serves as the main indicator of the successful implementation of 3R principles in significantly reducing environmental impact.

🗂️ Waste Management

As a continuation of our environmental commitment, Pupuk Kaltim implements a Waste Management Policy to reduce generation while improving the effectiveness of waste management across all operational areas.

This policy integrates management innovation, implementation of circular economy principles, and the concept of Extended Producer Responsibility (EPR) to create added value from operational waste materials.

Waste Reduction Target

Waste Generation Target 2024

Pupuk Kaltim targets a 3% reduction in waste generation over a five-year period. As a reference for achievement, for waste generation in 2024, the target for waste generated is no more than 1,407.40 metric tons, which serves as the basis for evaluating program effectiveness in subsequent years. Through source separation strategies, increased recycling, and innovation-based management, Pupuk Kaltim continues to strengthen its contribution to the implementation of sustainable environmental policies and the achievement of Sustainable Development Goals (SDGs).

🔄 Circular Economy

Pupuk Kaltim integrates circular economy principles into its waste management system to create closed loops that optimize resource utilization and minimize waste. This approach not only reduces environmental impact but also creates economic value from materials previously considered as waste.

Through the implementation of the Extended Producer Responsibility (EPR) concept, the company takes full responsibility for the product life cycle, from design to end-of-life management, thereby encouraging innovation in the development of more environmentally friendly and sustainable products.

🎯 Contribution to SDGs

Through the implementation of a comprehensive and sustainable waste management system, Pupuk Kaltim contributes directly to achieving the Sustainable Development Goals (SDGs), particularly in aspects of responsible production and consumption, environmental protection, and sustainable infrastructure development. Every waste management effort is designed to support the global vision of sustainable development while maintaining operational efficiency and company competitiveness.

🧪 Pollutant

COD Pollutant

As a manifestation of commitment to sustainable environmental management and compliance with wastewater quality standards in accordance with applicable regulations, Pupuk Kaltim consistently monitors and manages Chemical Oxygen Demand (COD) across all its operational facilities. The COD parameter serves as one of the main indicators in assessing the levels of organic compounds in wastewater, reflecting the effectiveness of liquid waste management from production processes and company utilities.

| Chemical Oxygen Demand (COD) | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| Unit (Ton) | 268,198.22 | 129,793.63 | 140,201.23 | 274,265 |

| Coverage (percent) | 100 | 100 | 100 | 100 |

Target 2024

Maximum COD target for 2024

🌬️ Air Pollution Reduction Policy

Pupuk Kaltim recognizes that the potential for air pollution is an inseparable consequence of industrial activities, including company operations. As a form of environmental responsibility, Pupuk Kaltim is committed to reducing air pollution burden through the Air Pollution Reduction Policy that emphasizes emission control from production processes, utilities, and supporting activities.

Monitoring is conducted on significant parameters such as Ammonia (NH₃), dust (PM), Sulfur Dioxide (SO₂), Nitrogen Oxide (NOx), and Fluorine (F) in accordance with PermenLHK No. 17 of 2019 concerning Emission Quality Standards. In 2024, the company targets total air emission loads not exceeding 3,900 tons for SO2 and 3,200 tons for NOx emissions as a manifestation of compliance and efforts to maintain sustainable environmental performance.

📊 Parameter Pemantauan Emisi

PKT conducts comprehensive air emission monitoring for key parameters that have been established in environmental regulations. Monitoring is carried out continuously through a Continuous Emission Monitoring System (CEMS) that can monitor emissions in real-time and is directly connected to the emission monitoring system of the Ministry of Environment.

Ammonia (NH₃)

Primary parameter from fertilizer production process

Dust (PM)

Suspended particles from industrial activities

Sulfur Dioxide (SO₂)

Emissions from combustion and utility processes

Nitrogen Oxide (NOx)

Gas from combustion and chemical reactions

Fluorine (F)

Chemical component from production process

CEMS

Continuous Emission Monitoring System

All these monitoring parameters refer to PermenLHK No. 17 of 2019 concerning Emission Quality Standards, ensuring that every PKT operational activity is carried out within safe limits and is responsible to the environment and surrounding communities.

🎯 Air Emission Targets 2024

As a manifestation of commitment to reducing air pollution burden, PKT has set strict emission targets for 2024. These targets are established based on in-depth analysis of production capacity, technology efficiency, and compliance with applicable environmental regulations.

SO₂ Emission Target 2024

Sulfur Dioxide from combustion and utility processes

NOx Emission Target 2024

Nitrogen Oxide from combustion and chemical reactions

These targets serve as daily operational guidelines for PKT in carrying out all production activities. Achievement of these emission targets demonstrates the company's commitment to maintaining air quality and contributing positively to the environment around the operational area.

⚙️ Efficiency and Environmentally Friendly Technology Programs

Within the next five years, Pupuk Kaltim targets a 1% reduction in conventional emission loads through a series of energy efficiency programs and implementation of environmentally friendly technologies. This reduction will be achieved by optimizing production equipment performance, improving combustion system effectiveness, and maximizing the function of emission control equipment.

Conventional Emission Reduction Target

Environmentally Friendly Technology Focus

Equipment Optimization

Production equipment performance improvement

Combustion System

Combustion system effectiveness

Emission Control

Maximize control equipment function

In addition, the company also encourages increased use of clean energy and continuous emission monitoring. Through these measures, Pupuk Kaltim not only strives to comply with environmental regulations, but also demonstrates a strong commitment to emission reduction and air quality improvement around the company's operational areas consistently and measurably.

Sustainable Product Management

As part of our commitment to environmental sustainability and responsible product innovation, Pupuk Kaltim implements sustainable product management that includes Life Cycle Assessment (LCA) studies, environmentally friendly product development, and research strategies oriented towards future agricultural solutions.

All product management efforts are carried out with principles of sustainability, environmental transparency, and sustainable innovation that support the achievement of net zero emission targets and positive contributions to Indonesia's agricultural ecosystem.

🔍 Life Cycle Assessment (LCA) Study

As part of strengthening sustainability performance, PKT has conducted Life Cycle Assessment (LCA) studies to identify and evaluate potential environmental impacts at every stage of the production process, from raw material selection, conversion processes, to product distribution. This study is conducted to comprehensively understand the environmental footprint of operational activities, so the company can set priorities in effectively reducing environmental impact.

Based on the Life Cycle Assessment (LCA) study conducted on 100% of urea products from PT Pupuk Kalimantan Timur (PKT), it is known that the urea production process has various potential environmental impacts at each stage of its life cycle — from cradle (raw materials), gate (production process), to grave (post-production). These impacts include global warming potential (GWP), ozone depletion, acid rain, eutrophication, photochemical oxidation, toxicity, as well as water and energy usage.

Global Warming Potential

Analysis of global warming potential from production processes

Water & Energy Usage

Evaluation of efficient water and energy usage

Emission Control

Identification of emission sources for process optimization

The study results show that environmental improvement potential can be focused on several main units, which contribute significantly to emissions and energy consumption. In addition, PKT has conducted comprehensive data inventory related to the use of raw materials, energy, water, and emissions from all production processes to support the development of a national LCA database.

📋 LCA Supporting Documents

Environmentally Friendly Products (EPD)

Environmental Product Declaration (EPD) is an environmental certification that provides transparent and verified information about a product's environmental impact throughout its life cycle — from raw material selection, production processes, distribution, to the final stage of the product.

As a pioneer in sustainable fertilizer industry in Indonesia, PT Pupuk Kalimantan Timur (PKT) has obtained EPD certificate S-P-04685 from EPD Southeast Asia, which shows that PKT products are produced with attention to energy efficiency, waste management, and carbon emission reduction.

Energy Efficiency

Optimization of energy usage in production processes

Waste Management

Responsible waste management system

Emission Reduction

Commitment to reduce production carbon footprint

🏅 EPD Southeast Asia Certificate

Environmental performance transparency for greener and more sustainable production

Through this achievement, PKT reaffirms its commitment to environmentally friendly products, supports environmental performance transparency, and contributes to global efforts towards greener and more sustainable production.

🔬 Sustainable Product Development

Pupuk Kaltim's research and product development strategy refers to the Indonesia Fertilizer Research Institute policy as a research unit of the parent holding PT Pupuk Indonesia. The strategic pillars of IFRI are as follows:

Customer Centric R&D

Developing products that meet plant nutritional needs

Agro Solution

Developing agricultural solutions to create consumer engagement

Research Institute

Building research institutes and conducting market research and policy advocacy

R&D Operating Model

Strengthening R&D Operating Model and solid organization

Through IFRI policies, the mechanism for sustainable product development at Pupuk Kaltim establishes evaluation criteria and product classification that includes three important characteristics, namely:

Sustainable Raw Materials

Selection of renewable and environmentally friendly resources

Environmentally Friendly Technology

Implementation of production processes that minimize environmental impact

Usage Efficiency

Reducing losses and improving nutrient absorption

🌿 Environmentally Friendly Products

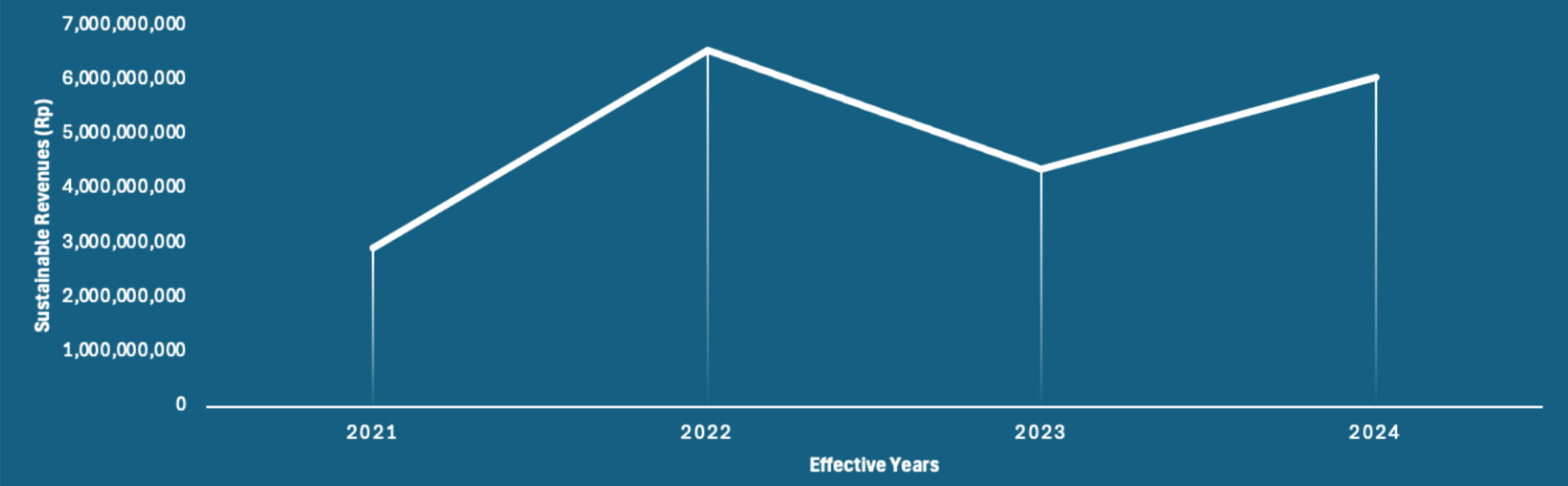

💰 Sustainable Revenue from Environmentally Friendly Products

Economic contribution from Pupuk Kaltim's sustainable product innovation

In addition to main products such as Urea, Ammonia and NPK, Pupuk Kaltim has developed environmentally friendly products through research and development. These products include the following:

♻️ Circular Economy

Pupuk Kaltim is committed to implementing Circular Economy principles to create more efficient, sustainable, and environmentally friendly production processes. Through optimal resource management, the company drives transformation from the linear economic model "take–make–dispose" to a system that focuses on reuse, recycling, and waste reduction in every business process chain.

The implementation of Circular Economy is realized through various strategic initiatives, including optimization of raw material use, improvement of energy efficiency, utilization of waste into value-added products, and development of clean technology in production operations. Solid, liquid, and gas emission waste is managed sustainably, including the utilization of industrial by-products as reuse material that supports the productivity of the agricultural and other industrial sectors.

Pupuk Kaltim also encourages collaboration with suppliers, business partners, and local communities in strengthening awareness of circular economy practices. Through this approach, the company strives to reduce carbon footprint, save natural resources, and ensure the sustainability of national fertilizer production in the long term.

By integrating Circular Economy into operational culture and technological innovation, Pupuk Kaltim plays an active role in supporting the Sustainable Development Goals (SDGs) agenda, creating industrial efficiency, improving environmental sustainability, while driving economic added value for all stakeholders.

🔄 Pupuk Kaltim's Circular Economy Approach

01. 🏭 Smart Production

Pupuk Kaltim improves production process efficiency through:

- Optimization of raw material and natural gas consumption

- Implementation of Smart Production digitalization

- Data-based energy efficiency

- Process engineering to minimize off-spec material

Product design and operations are oriented towards life cycle efficiency and environmental impact reduction.

02. 🤝 Responsible Caring

In the use and consumption phase, Pupuk Kaltim implements:

- Environmental impact labeling (Environmental Labels)

- Life Cycle Assessment (LCA) analysis

- Educational programs for farmers on balanced fertilizer use

- Promotion of precision agriculture technology to reduce soil and water residues

This approach supports agricultural economic growth without increasing ecological pressure.

03. ♻️ Waste Management

In the waste management stage, Pupuk Kaltim develops:

- Water recycling for operational processes

- Utilization of by-products as raw materials for other industries

- Zero Waste to Landfill roadmap

- Research collaboration with external parties to convert waste into new products

Cross-supply chain waste utilization strengthens ecosystem connectivity.

📈 Results and Added Value

The implementation of Pupuk Kaltim's Circular Economy produces sustainable benefits:

🌱 Long-term carbon emission reduction

⚡ More efficient energy use

💧 Water consumption savings

🗑️ Waste disposal minimization

🏆 Industrial competitiveness strengthening

This initiative is in line with the Sustainable Development Goals (SDGs), increasing national productivity, and contributing to the decarbonization of the agro-industrial sector.