Description

NPK fertilizer produced by Pupuk Kaltim consists of two types, namely NPK Blending and NPK Fusion. NPK is made in various compositions, according to the needs of the plant and the type of soil. This type of fertilizer contains three macro nutrients needed by plants. The raw materials for NPK are urea, DAP (Diammonium phosphate)/RP (Rock phosphate), KCl (Potassium chloride), and other materials in the form of high quality micronutrients.

The Company has two NPK plants with two processing technologies. The NPK Blending plant has a production capacity of 100,000 tons/year, while the NPK Fusion plant 200,000 tons/year. Thus, the total production capacity of NPK is 300,000 tons/year. Non-subsidized NPK fertilizers are marketed under NPK Pelangi brand. At the end of 2020, the packaging for NPK Pelangi underwent a visual change as shown in the pictures, and had a variety of packages of 2 kg, 5 kg, 10 kg, 20 kg and 50 kg.

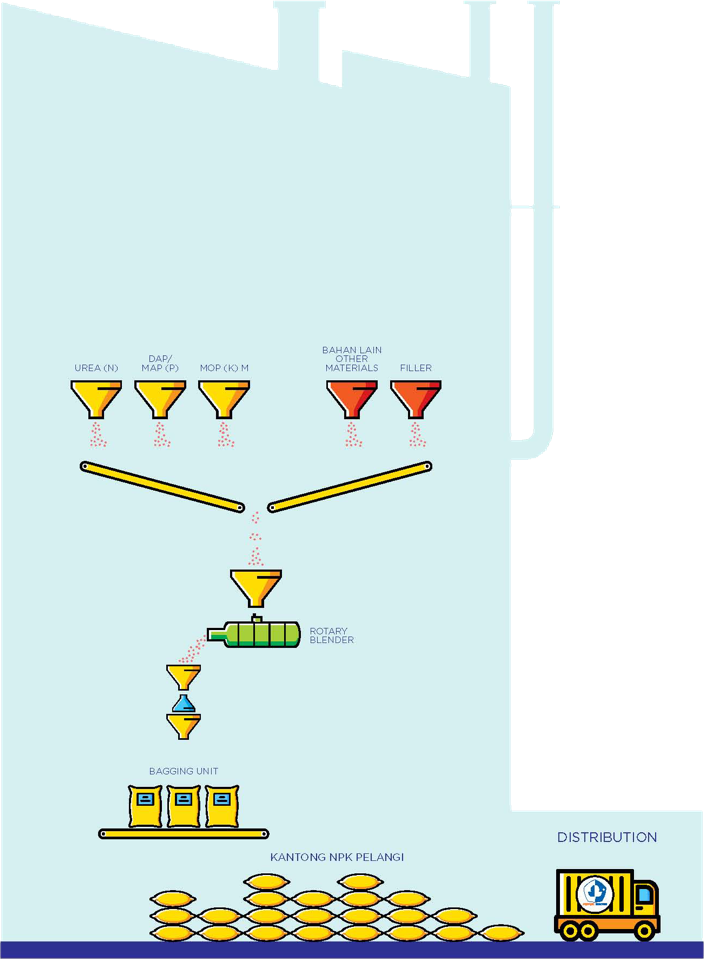

NPK Pelangi fertilizer consists of two types, namely NPK Blending and NPK Fusion. The Blending-type NPK Pelangi is produced through a mechanical blending process and formed from high quality raw materials i.e. urea granules, DAP (Diammonium Phospate) and KCL Flake, as well as fillers such as Mg and Ca so that the granules are colorful.

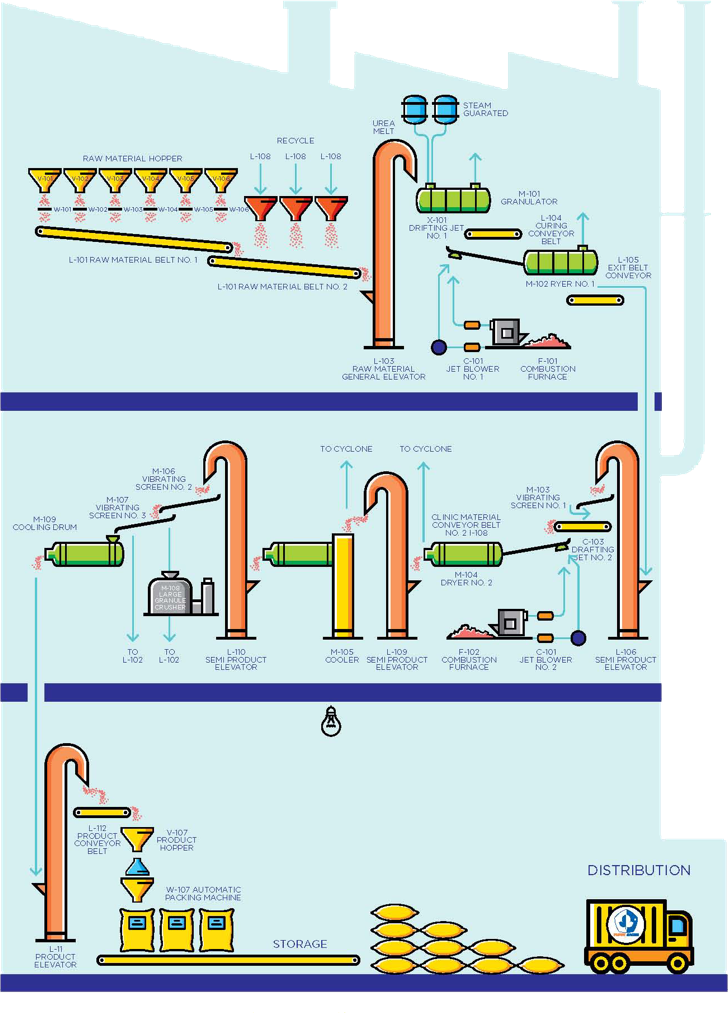

Meanwhile, the Fusion-type NPK Pelangi is produced through a steam granulation process so that it has homogeneous fertilizer granules containing N, P and K elements in one grain. The advantage of NPK Pelangi is that it can be formulated very flexibly according to customer needs, and is proven to be able to increase crop yields.

NPK SPECIAL FORMULA

Subsidized NPK is also marketed under NPK Pelangi brand, specifically for cocoa commodity, which is distributed in the provinces of South Sulawesi, West Sulawesi, Southeast Sulawesi and Central Sulawesi and packaged in 50 kg.

Proses Produksi

NPK Blending Production Schema

NPK Fusion Production Schema

MSDS

Material Safety Data Sheet

The Safety Data Sheet (SDS) is an instruction sheet/document containing chemical material information such as material characteristics (physical and chemical), potential dangers, methods of handling, special action in emergencies, and other necessary information.

The document plays an important role in ensuring occupational safety in the handling of chemicals. SDS provides information on the correct procedures in transportation, storage before use, handling during use, and emergency special handling up to disposal of the chemicals after use. Every employee who uses chemicals must read the SDS material for personal, material, and environmental safety.

Chemical manufacturers are obliged to provide SDS for the chemical products they produce according to national and international regulations.