Comprehensive Risk Management: Pillars of Sustainability and Growth

Pupuk Kaltim is committed to delivering maximum benefits to shareholders and all stakeholders. We recognize that in every business practice, there are elements of uncertainty—both from internal and external environments—that can affect the achievement of company objectives. In the midst of a dynamic and increasingly complex business climate, these uncertainties become risks that cannot be avoided, but must be managed professionally through a robust risk management framework.

Implementation Foundation and Framework

To ensure that every risk is managed effectively, Pupuk Kaltim has developed a systematic and integrated Enterprise Risk Management (ERM) system. The implementation of ERM in the company environment is guided by the best standards recognized globally and nationally, including:

ISO 31000:2018

GLOBAL STANDARDRisk Management – Principles and Guidelines, as the international standard for comprehensive risk management principles and guidelines.

ISO 22301:2019

GLOBAL STANDARDBusiness Continuity Management, to ensure resilience and operational continuity of the company under all conditions.

SOE REGULATION NO PER-2/MBU/03/2023

NATIONAL REGULATIONState-Owned Enterprises Ministry Regulation, as the foundation for governance and significant corporate activities for State-Owned Enterprises.

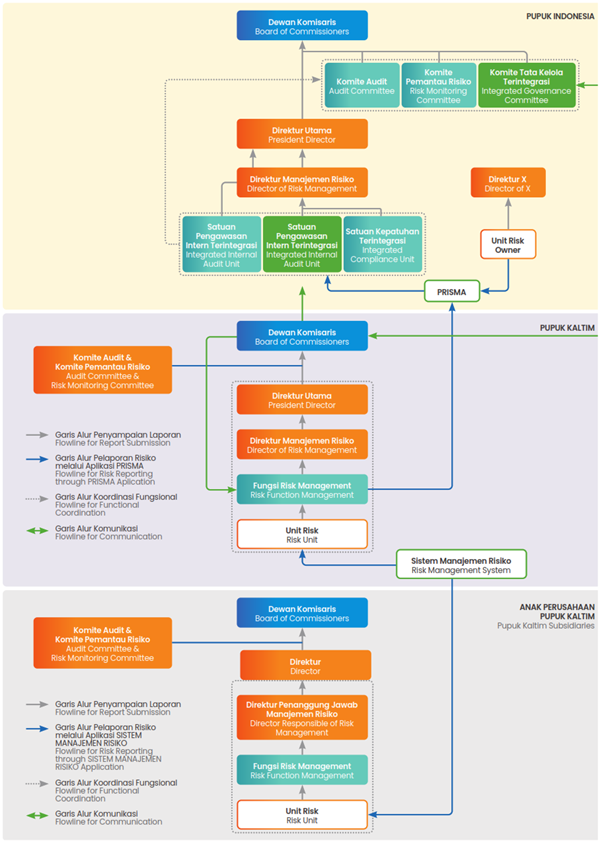

Risk Governance and Three Lines Model

Pupuk Kaltim believes that Good Corporate Governance (GCG) and effective Risk Management are fundamental pillars for achieving sustainable growth and creating long-term value. In line with strategic direction from the parent company, PT Pupuk Indonesia (Persero), this system is carefully designed to ensure strong oversight, clear accountability, and embed a risk-aware culture throughout all organizational lines. This commitment is realized through a robust governance structure and layered defense mechanisms.

The governance structure at Pupuk Kaltim is built in three integrated levels, ensuring alignment from strategic to operational levels. At the Board of Commissioners level together with the Risk Monitoring Committee, they carry out oversight functions to ensure strategic policies are implemented with prudential principles. At the next level, the Board of Directors represented by the Risk Management Director is fully responsible for risk management implementation. At the frontline, each business line is tasked with identifying, analyzing, and proactively mitigating daily risks.

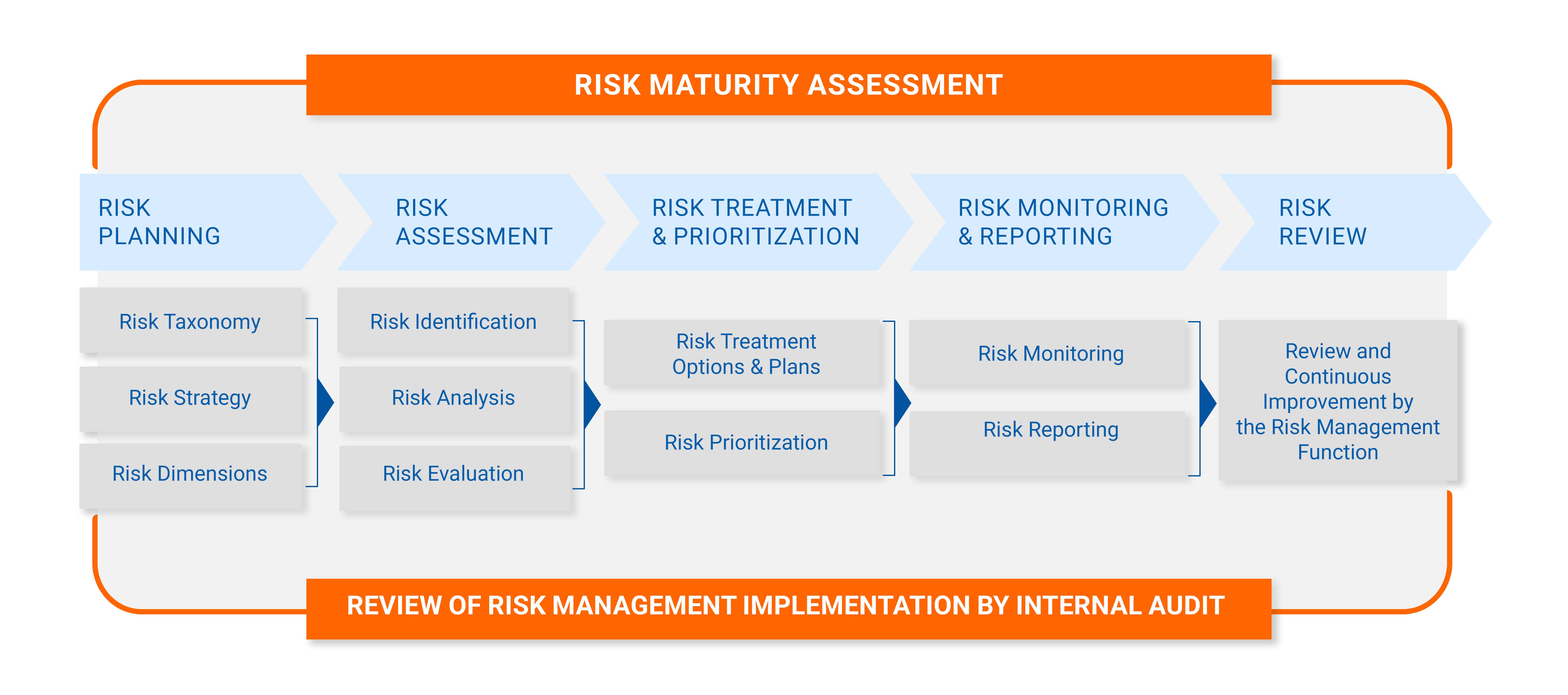

Risk Management Process

Pupuk Kaltim implements a structured and sustainable risk management process to ensure that every potential risk can be identified, evaluated, and mitigated effectively across all business lines.

The risk management process at Pupuk Kaltim consists of several integrated stages, including:

Emerging Risk Monitoring

As a company operating in the fertilizer industry sector, Pupuk Kaltim faces various challenges that can affect operational continuity and the company's long-term strategy. In facing the dynamics of a continuously developing global market and increasingly complex regulatory changes, the company needs to identify and manage emerging risks—risks that have not yet fully materialized but have the potential for significant future impact.

By actively scanning the horizon, Pupuk Kaltim is not only reactive to existing problems, but also proactive in building resilience and agility to face challenges that are not yet fully visible. By understanding and anticipating these risks, Pupuk Kaltim strives to maintain business sustainability and maintain competitiveness in an increasingly competitive market.

Gas Price Volatility

Economic / GeopoliticalRisk Description

Pupuk Kaltim is highly dependent on natural gas as the main raw material in the fertilizer production process. Natural gas is used in ammonia production, which then becomes the raw material for the Company's core product, urea production. The natural gas supply needed is entirely obtained from local suppliers in East Kalimantan through a 60 km pipeline from Muara Badak to production facilities in Bontang. In 2024, total natural gas purchases for production reached Rp10.53 trillion, an increase compared to the previous year which was recorded at Rp9.81 trillion.

As the main raw material that is fully managed by the government, natural gas places Pupuk Kaltim in a position that is very vulnerable to changes in government policies related to gas prices, such as price increases or subsidy reductions. Changing gas pricing policies can affect production cost stability and disrupt the company's operational smoothness. In the production process, natural gas also produces CO2 as a by-product, which is used in the manufacture of other fertilizers. Along with the increase in ammonia production by 1.77% in 2024, the use of natural gas for raw materials also increased by 0.70% compared to the previous year.

Risk Source

External (regulation, global energy market, geopolitical conditions)

Time Frame

Long TermPotential Impact

Unexpected gas price changes can have a direct impact on the company's operational costs. If there is a significant increase in gas prices or reduction in gas subsidies, the company will face increased production costs, which could potentially reduce profitability. In the long term, these policy changes could affect the competitiveness of Pupuk Kaltim products in both domestic and international markets. In addition, dependence on natural gas supply that is fully managed by the government increases supply uncertainty that can disrupt production smoothness.

Mitigation Actions

- Implementing energy efficiency in production processes to reduce dependence on natural gas.

- Energy source diversification by exploring the use of renewable energy or other more stable energy sources.

- Coordinating with the government to ensure sustainable gas pricing policies that support the continuity of the fertilizer industry, including advocacy to maintain gas price stability so as not to affect company operations.

Opportunities

- Technology innovation and energy source diversification for low-carbon production and energy efficiency

- Strategic collaboration for long-term gas supply

Risk Study

As part of its commitment to implementing an integrated and sustainable risk management framework, Pupuk Kaltim consistently conducts risk assessments for every corporate and non-corporate action, including development projects. This assessment is prepared by referring to the Enterprise Risk Management (ERM) framework and the applicable regulations within the state-owned enterprise (BUMN) environment.

Through this assessment, the Company ensures that every potential risk is properly identified and managed to maintain business stability and continuity, covering financial risks, market risks, legal and compliance risks, as well as operational risks.

Risk Culture

Risk management at Pupuk Kaltim is not only about procedures and systems, but also about building culture. We emphasize the importance of implementing risk management that becomes part of the DNA of every company employee. For this purpose, we continuously provide various development programs to increase awareness and capabilities of executives and employees.

Investment in this competency aims to ensure that the company is not only reactive to risks, but also proactive in identifying opportunities amid uncertainty. Thus, Pupuk Kaltim is able to face challenges effectively, achieve its business strategy, and continue to grow sustainably.

Building Business Resilience:

Integration of SMKU ISO 22301:2019 and Financial Contingency Plan (FCP):

As a comprehensive contingency measure, Pupuk Kaltim implements the ISO 22301:2019 Business Continuity Management System (BCMS) to ensure resilience in responding appropriately to crisis conditions and to carry out effective financial and operational recovery in the event of a disaster that could cause the interruption of critical business functions, which could result in losses for the Company. Supported by a financial contingency plan (FCP) as an indicator that helps the Company monitor its condition.

The synergy between these two systems demonstrates the Company's commitment to prudence. We do not only focus on protecting shareholder value, but also on maintaining the trust of all stakeholders. This resilience ultimately becomes a driving force for achieving sustainable business targets and strengthening a healthy risk management-based performance incentive formula.

📋 Company Policies

Pupuk Kaltim openly shares company policies that demonstrate our commitment to becoming a sustainable business in the long term.

ESG & Human Rights Policy

Good Corporate Governance Guidelines

Supplier Code of Ethics

Fraud Control Guidelines

Anti-Bribery and Gratification Guidelines

Whistleblowing System Guidelines

Respectful Workplace Policy

Risk Management Guidelines

Conflict of Interest Management Guidelines

Code of Ethics Guidelines

Information Security Management System Policy

Green Industry Policy

Asset Management System Policy

CSR Management System Guidelines

Green Building Management System Policy

Business Continuity Management System Policy

Compliance Management System Policy

Anti-Bribery Management System Policy

Quality Management System Guidelines

Security & ISPS Code Management System Policy

Production Management System Policy

Integrated Management System Policy

Energy Management System Guidelines

Environmental Management System Guidelines

Laboratory Quality Management System Guidelines

Quality Management System Guidelines

Occupational Health & Safety Policy

Environmental Policy

Waste Management Policy

B3 Waste Reduction and Utilization Policy

Air Pollution Reduction Policy

Life Cycle Assessment Policy

Biodiversity Protection Policy

Water Efficiency and Wastewater Pollution Reduction Policy

3R Non-B3 Solid Waste Policy

Climate Risk Asssesment

Pupuk Kaltim telah mengidentifikasi physical risk yang merupakan dampak dari perubahan iklim yang memiliki dampak potensial atau signifikan terhadap keberlanjutan Perusahaan. Risiko iklim Pupuk Kaltim yang telah teridentifikasi sebagai berikut:

- Terlambatnya loading urea karena cuaca yang tidak menentu dan ekstrem, sehingga adaptasi yang dilakukan Pupuk Kaltim adalah dengan meningkatkan kecepatan loading urea curah dengan cara menggunakan 2 BSL sekaligus untuk loading urea ke 1 kapal, memerkuat infrastruktur pelabuhan dan fasilitas loading melalui penambahan atas pelindung

- Menurunnya kualitas produk karena terkena air hujan dari cuaca ekstrem badai. Adaptasi yang dilakukan oleh Pupuk Kaltim adalah penggunaan container untuk distribusi urea kantong, melakukan pembangunan atau renovasi infrastruktur dengan mempertimbangkan factor-faktor iklim

- Terlambatnya kedatangan kapal sampai distribusi ke Gudang lini II dan III karena cuaca ekstrem badai yang dapat mengganggu distribusi dan pendapatan Perusahaan, reputasi dan kepercayaan konsumen. Adaptasi yang dilakukan oleh Pupuk Kaltim adalah dengan membuat aplikasi Distribution Planning and Control System (DPCS) dengan pemasangan GPS pada kapal untuk mengetahui posisi kapal secara real time, memiliki beberapa rute pengiriman yang berbeda untuk menghindari area yang rawan terkena dampak badai

- Terlambatnya kedatangan kapal bahan baku pupuk NPK karena cuaca ekstrem badai yang mengakibatkan terhambatnya operasional pabrik, terganggunya reputasi dan menurunnya tingkat kepercayaan konsumen. Adaptasi yang dilakukan adalah dengan melakukan pengaturan ulang jadwal produksi pupuk untuk menghindari kekurangan pasokan dan memastikan bahwa stok yang ada dapat mencukupi permintaan, pencarian sumber bahan baku alternatif yang lebih cepat, mengoptimalkan stok bahan baku yang ada, melakukan komunikasi dengan pelanggan, melakukan inovasi dengan pemanfaatan teknologi dalam memantau kondisi cuaca secara real time.

- Berkurangnya efektivitas pendingin sweet cooling water karena adanya peningkatan suhu air laut, yang berdampak pada tidak optimalnya pendinginan pada proses produksi sehingga produksi menurun dan tidak efisiennya proses produksi. Adaptasi yang dilakukan oleh Pupuk Kaltim adalah dengan melakukan adjustment kondisi operasional termasuk menurunkan rate produksi, menambah kapasitas Marine Plate Heat Exchanger (MPHE) untuk memperbesar heat transfer antara sweet cooling water dengan air laut.